Our engineers offer cutting-edge technical support services to assist our customers with custom product consultation, design, cost reduction analysis, and many other services. In addition to following our customer’s specifications, we are committed to and comply with industry-standard practices and procedures.

Reverse Engineering

Heymed Technology engineering team can reverse engineer and create documentation for production. The reverse engineering process includes creating BOM, drawings, test requirements, and detailed work instructions for consistency and repeatability of the product.

NPI Products

New Product Introduction: Heymed technology engineering team can help customers transfer from an idea or a rough sketch into products that meet cable requirement specifications. Heymed technology can quickly turn customer ideas into a prototype and full turn-key product. Heymed Engineering team will help our customers to optimize their design for ease of manufacturing and reduced production costs.

Project Management

Heymed engineering team experienced work with customers by managing projects for their cable harness and electro-mechanical products. Project management includes sourcing raw material, documentation, supply chain qualification, prototype sample, and ramp-up to high volume production.

On-Site Technical Support

Heymed engineering team can also provide On-Site technical support as required by the customer, especially at the initial stages of the design to assure that the cable assemblies have no issues in the ramp-up production and are fully qualified for DFM.

Alternate Parts

Heymed engineering team can help customers by suggesting alternate/equivalent part(s) for products that can reduce lead time, improve quality, or reduce the cost.

Drawings & Documentation

Heymed engineering team can create custom drawings using AutoCAD and Solid Works. Drawings can be customized to add a logo or any special assembly feature that customers require. Heymed drawings capture key assembly processes, quality checkpoints, and manufacturing standards.

First Article Inspection

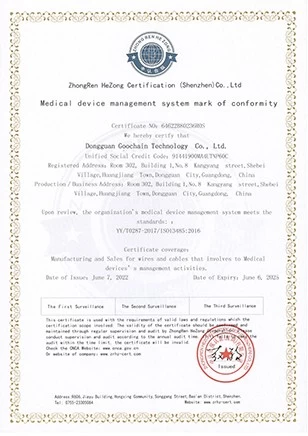

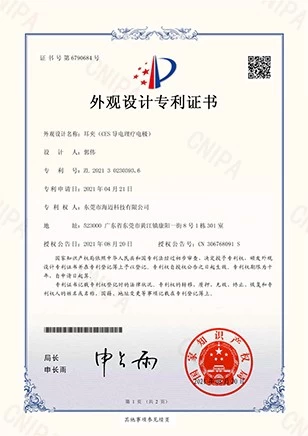

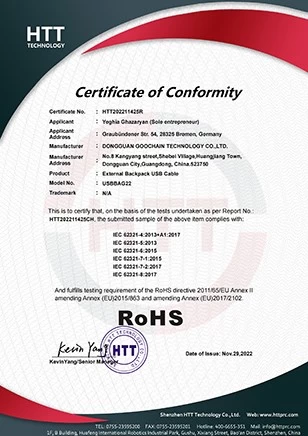

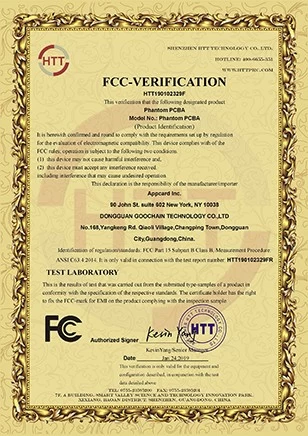

Heymed dedicated and experienced engineering team is responsible for first article inspection (FAI) that captures all the aspects for the product from quoting to shipping. At the first article stage we work with customer as a partner to assure that all the drawing, component specification, assembly process, tooling /test fixture are documented for consistent and repeatable high quality product. At the first article stage Heymed engineering team help customer to make sure that any certifications as UL, RoHS, REACH, IPC-WHMA-A-620, IPC-610 etc. all documented and clarified to meet the system level requirements.